the Construction Industry

About Vruddhi Coupler

Vruddhi Engineering Works Limited caters to the need for mechanical splicing solutions in the construction Industry. Formerly known as Kosmo Venture, we are a leading supplier and exporter of Rebar Couplers backed by vast experience and expertise. We provide end to end mechanical splicing solutions ranging from design, testing, logistics and rebar threading. Vruddhi Engineering Works Limited is ISO-9001:2015 accredited.

Conventional Splicing

Mechanical Splicing

Vruddhi Rebar Couplers are suitable to join the reinforcement bars end to end. Couplers are an efficient alternative for traditional lap splice or overlapping joints. Cost benefit analysis show that use of threaded rebar couplers is a cost effective method as compared to old method of lap splicing / overlapping joints.

Vruddhi Rebar Couplers are readily available for rebar diameter ranging from 16 mm to 40mm. We can customize our products to meet your specific requirement.

Benefits

Couplers

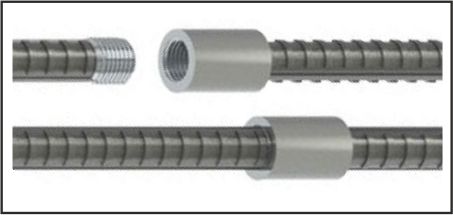

Vruddhi Parallel Threaded Couplers

Vruddhi Cold Forged Couplers

Vruddhi Transition Couplers (Reducer Couplers)

We also offer End Anchors (Terminator Couplers) which provide end anchorages in congested areas.

The combination of advance technology and human resource excellence enables us to customise our products to diverse applications and specific customer preferences.

Rebar Cold Forging Machine

Rebar Roll Parallel Thread

On-site Threading

To facilitate the use of Vruddhi Couplers, we offer on-site threading service. Our skilled and experienced workforce shall take care of all the hassles associated with on-site machine installation and rebar threading.

Splicing Method

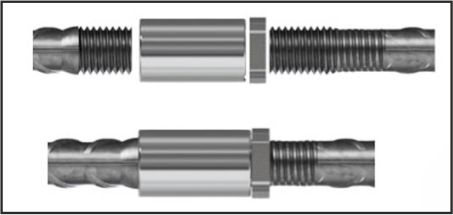

Type A

It is used when at least one connecting rebar can be rotated. Both the rebars are threaded for half the length of the coupler.

Type B (Position Rebar Coupler)

It is used in applications where none of the Re-bar can be rotated. One bar is threaded for full coupler length and the other is threaded for half of coupler length. Typical applications include prefabricated cages, bent bars and precast structural elements.

Bar-End Preparation

Vruddhi Cold Forged Couplers

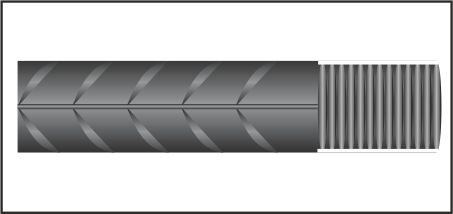

1. Forging

The reinforcing bar is enlarged by cold forging process, thus increasing its diameter

2. Threading

Standard ISO metric threads are then cut onto the enlarged end

3. Mechanical Splicing

Finally splice the rebar by threaded Vruddhi cold forged coupler

Vruddhi Parallel Threaded Couplers

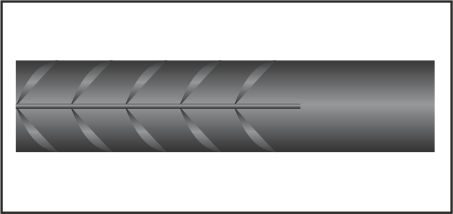

1. Peeling

The ribbing at the end of the rebar is peeled

2. Threading

The peeled end of the rebar is rolled thread as per stand ISO metric

3. Mechanical Splicing

Coupler can be used to connect the two rebars

Quality Assurance

Our ISO-9001:2015 certified facilities deploy best-in-class technology to deliver superior coupler system. Vruddhi Rebar Couplers are produced from carbon steel (mild steel) with minimum tensile strength of 600 MPa. Vruddhi Rebar couplers comply with strict technical specifications and governing standards of ACI 318, BS 970, IS 16172:2014 among others.

Vruddhi Couplers are subjected to following tests

- Chemical Composition Test

- Static Tensile Test

- Slip test

- Cyclic Tensile Test

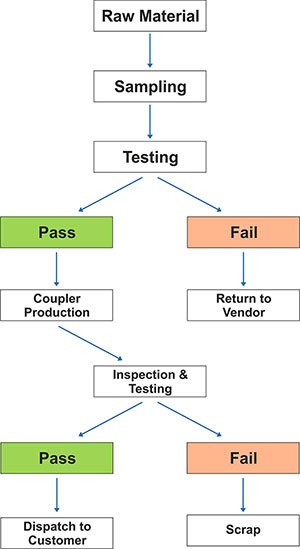

Process Flow

Awesome Clients We Work With

At Vruddhi, we understand that each of our customers is unique. We have and extensive portfolio of products that satisfy the needs of our customers regardless of the nature and size of the business.