Understanding applications of Vruddhi REBAR COUPLERS in RCC construction systems

Large scale civil engineering construction projects of skyscrapers require rebar couplers with scalability and durability. Other than their applications for tall buildings, they are also implemented in erecting bridges, dams and towers. Reinforcement couplers is a much better alternative to lapping which produces wastage and takes more time. It also supersedes the welding option.

Vruddhi Couplers use the technologically advanced mechanical splicing route to help clients to enjoy better services. We provide solutions that enhance the deliverability of the project. This post offers our guidelines related to applications of couplers and their implementation.

In our company we believe that anchorage and splices have an important and specific role to create a reinforced structural design. This is the key to accomplish goals in making secure joints when space is limited. Often cross bars are complicated and customers have to consider potential costs, construction timelines, feasibility in meeting all the codes and industry standards. Practical limitations are taken into consideration to ensure that couplers meet all the expectations. The same also happens when buildings are renovated and require rebar compositions.

Handling tricky rebar implementation

When it comes to a new project, the construction site offers lesser challenges. But when remodelling or renovation is required, it poses problems. Take for instance such a project where rebar couplers are required for a client who needs a new roof in an existing building which already has an original roof. A new steel roof can be made but the challenge lies in checking the support of the columns and pillars. Do they secure the foundation? Will they be able to take the new load? Will additional columns create issues? Which kind of rebar couplers would be ideal that have tensile strength and bear the load to keep the foundation strong? Can the company use a rebar without threading services?

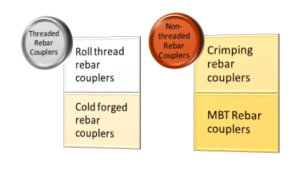

2 Types of rebar couplers and applications

For a renovating project the MBT rebar coupler can be implemented. No threading is involved in the process. The screw is fitted into the bar with a pre-determined torque. It enables a solid connection between the sides of the coupler and the bar.

The following image shows the way it is applied.

When structural changes are made rebars can be replaced with precision. However, it takes a skilled team to work on the same.

Vruddhi couplers have the experience and the knowledge to provide clients guidance to various new and renovating projects. We use our expertise in other projects where short lifts are required for masonry walls.

We help clients to even undergo the selection process of rebar couplers required for different projects. Depending on the demands check for the following factors:

Performance of different couplers – We do analysis and testing procedures to pick the right products.

Experiments and reviews- It adds to the testing of all mechanical splicers, their types and sizes which fit the onsite requirements.

We look out for strains, fractures and stress concentration of screws for dynamic loading. In some areas we need to look out for seismic performance.

If this information makes complete sense to you, do let us know how we can add value to your RCC structural requirement. Vruddhi Couplers are designed to beat any challenges and risks that your team faces.