Description

Vruddhi Cone Tie (VCT) is a specialized construction product used to secure formwork panels, ensuring precise alignment and uniform spacing. This enhances the quality and durability of concrete structures by maintaining consistent wall thickness and strength. VCTs are vital in complex projects, providing an effective alternative to conventional wall ties.

Key Features of Vruddhi Cone tie (VCT)

- Versatile: VCT is compatible with various formwork systems, making them a valuable construction resource.

- Leakage Protection: Leaving a rod inside the structure eliminates the need for through holes during grout filling, minimizing leakage points. This ensures uniform grout distribution, enhances sealing, and reduces structural leakage risk.

- Enhanced Stability: VCT provide precise alignment with formwork panels.

- Cost-effective: The cones at each end are reusable for the entire project, offering durability and environmental benefits.

- Improved Integrity: The sacrificial rod prevents through-holes in reinforced concrete, enhancing structural durability and reducing grout filling time.

Quality Assurance

Static tensile test

Vruddhi Cone tie (VCT) Specifications

- L1 – Designed as per width of the structure.

- L2, L3 – Designed as per formwork specification.

Vruddhi Cone tie (VCT) Installation Process

- Step 1 : Assembly of Cone Tie

- Step 2 : Installing cone tie in aluminium formwork

- Step 3 : Pour the ready mix concrete into the formwork.

- Step 4 : Remove the formwork once the mixture has solidified.

- Step 5 : Extract the end cones, leaving the rod inside the structure.

- Step 6 : Fill the small void with grout to achieve a proper wall finish.

Ensure a more leak-proof structure.

To know more about how Vruddhi Sonic Tubes can enhance your construction projects, contact us at +91 83697 05450.

Benefits

Process

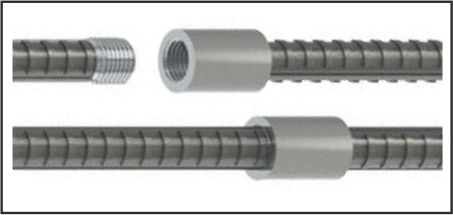

Step 1

90º cutting

Step 2

Forging

Step 3

Threading

Step 4

Couplers Fixing

Rebar Preparation Process

a) Cold Forged

- Flat cut rebars

- Cold forging

- Threading

- Coupler fixing

b) Parallel

- Flat cut rebars

- Threading

- Coupler fixing