Description

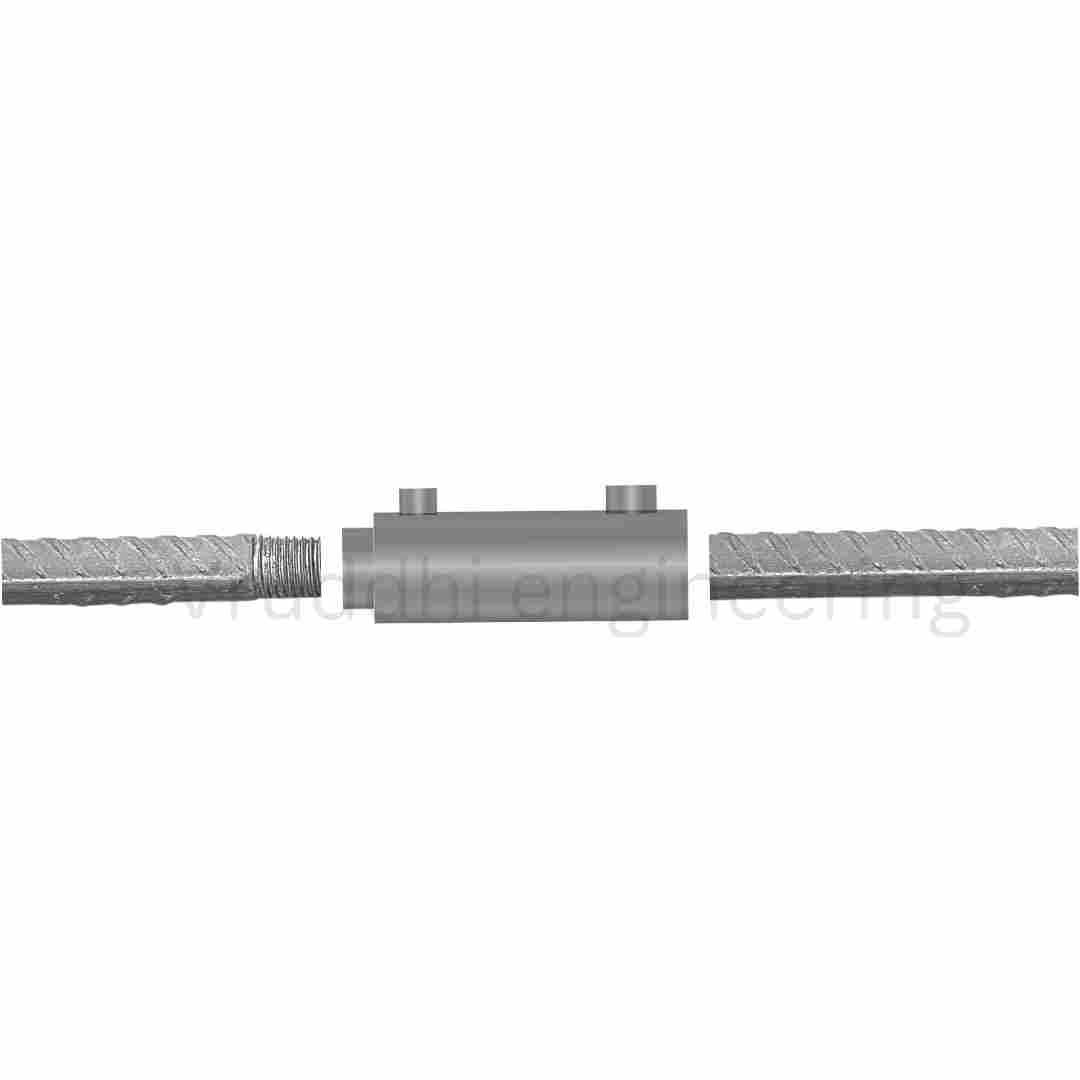

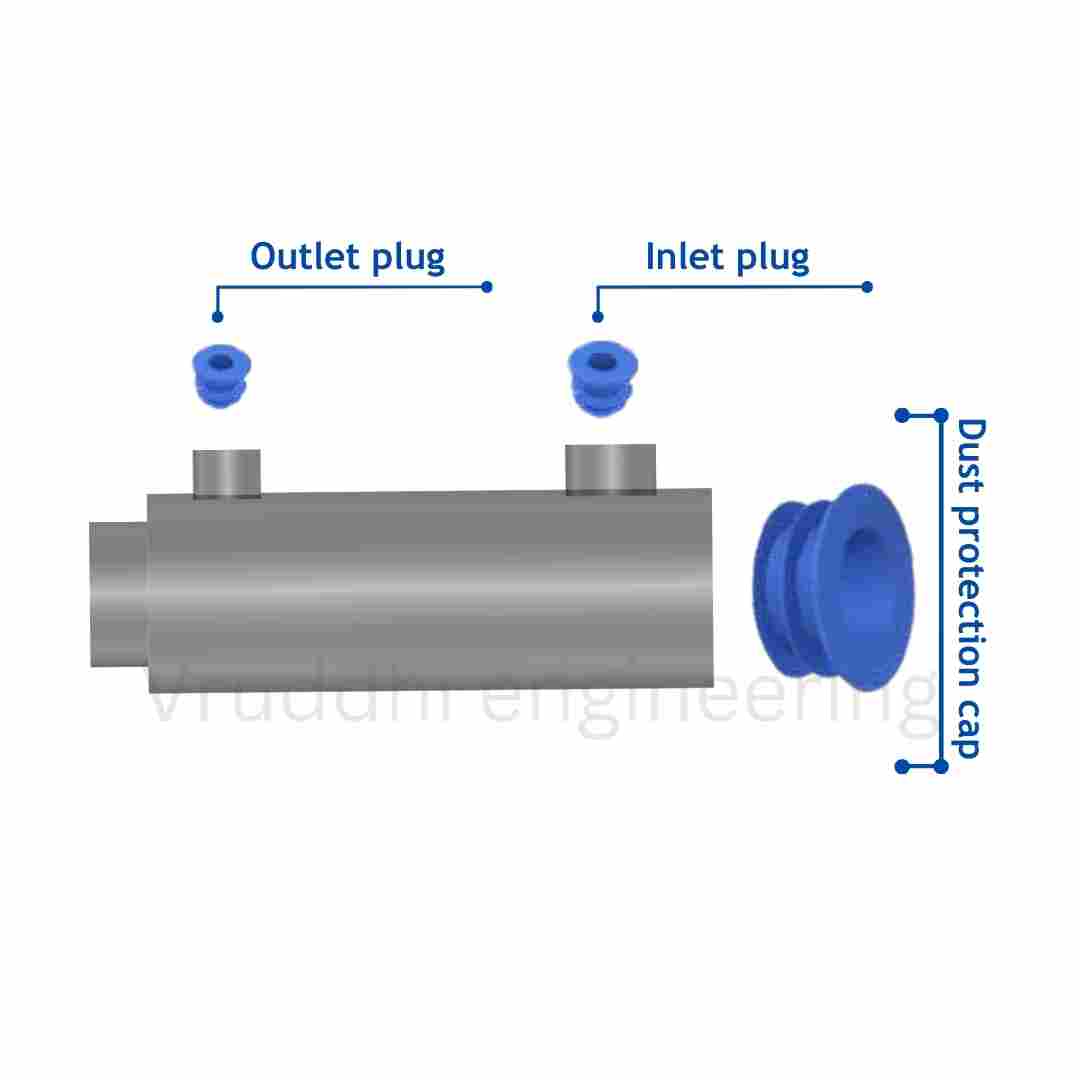

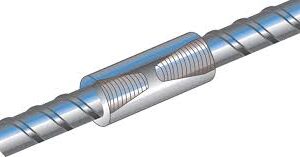

Vruddhi GroutFit Couplers are specially designed for connecting GroutFit elements. These half-grout

system couplers have one threaded end for rebar connection and a hollow cavity for connecting two GroutFit elements on-site.

Product Features

- Compatible with rebar grades up to Fe 550 D

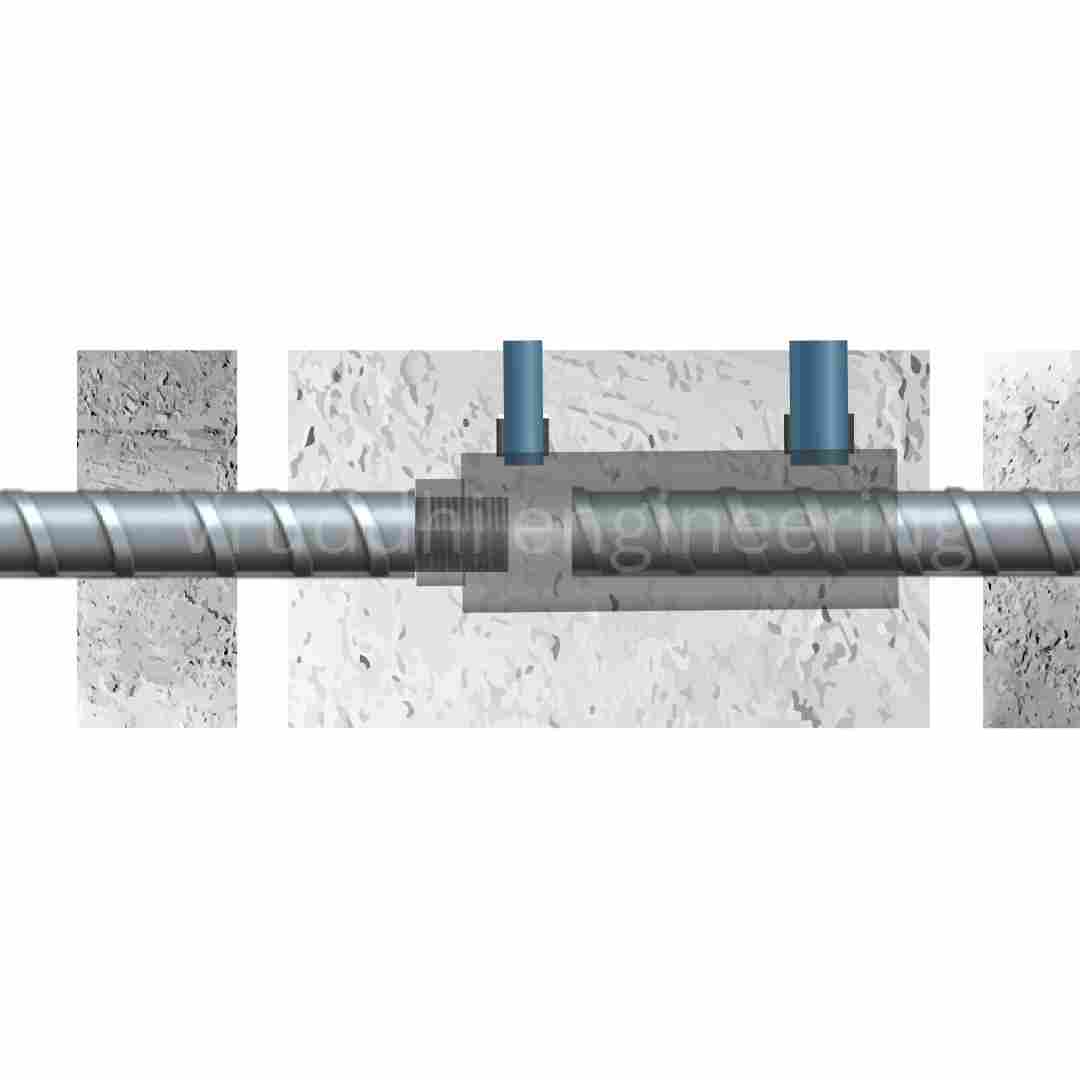

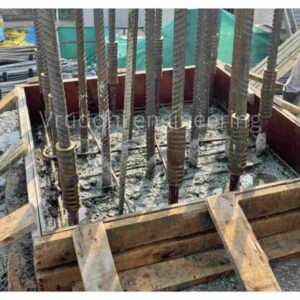

- Quick on-site connection by non-shrink grout

- IS 16172:2023 Compliance

- Minimum 3% elongation for the splice joint shall be achieved

- Compatible with both cold forged and roll threaded rebar ends

- Available for Sizes Ø 12 mm to 40 mm

Applications

- Connect two GroutFit elements

- Horizontal & Vertical connections

Rebar Preparation Process

- Cut the rebars to the necessary length.

- Thread one end of the rebar.

- Leave the other end of rebar to be inserted in Hollow cavity

- Connect the rebar with the threaded end to the GroutFit element.

- Pour Vruddhi grout to complete the connection.

Benefits

Cost Saving – Lesser Steel Consumption

Higher UTS Than That of Parent Rebar

Shortens Project Timeline

No Torque Wrench Required

Solves Bar Congestion

Improvement in Concrete Flow

Benefits

Experience a multitude of benefits when you choose Vruddhi Rebar Couplers:

- Cost Savings: Vruddhi Rebar Couplers offer substantial cost savings by reducing steel consumption in construction projects. This efficient alternative to lap joints not only lowers material costs but also shortens project timelines, minimizing labor expenses. The result is a significant overall reduction in construction expenditures, making Vruddhi Couplers a smart and cost-effective choice for your projects..

- Load Transfer Independence:

Vruddhi Rebar Couplers provide load transfer independence, ensuring the structural integrity of your construction

regardless of concrete quality or grade. This benefit guarantees consistent performance and reliability, reducing the risk of structural issues and offering peace of mind in diverse construction scenarios. - Project Timeline Shortening: Vruddhi Rebar Couplers expedite project timelines significantly. Their quick and efficient installation reduces construction duration, leading to earlier project completion. This time-saving advantage not only enhances project efficiency but also minimizes labor and overhead costs, making Vruddhi Couplers a valuable asset for timely project delivery.

- No Torque Wrench Required : Vruddhi Rebar Couplers offer the advantage of not requiring a torque wrench for installation. This simplifies the assembly process, reducing the need for specialized tools.

- Bar Congestion Solution: Vruddhi Rebar Couplers offer an effective solution by reducing congestion, ensuring proper concrete flow, and preventing potential weaknesses. This not only enhances structural strength but also guarantees the long-term durability of your construction projects.

- Improved Concrete Flow: Vruddhi Rebar Couplers facilitate improved concrete flow during construction. By

eliminating the need for lap joints and reducing rebar congestion, they create a smoother and more efficient concrete

pouring process. - Full Performance Rebar Splicing: Vruddhi Rebar Couplers guarantee full performance rebar splicing. Compliant with IS 16172 standards, they ensure reliable and robust connections in construction projects. This adherence to quality and strength specifications assures builders and engineers of consistent and dependable performance, vital for the integrity of structures.

Go/No-Go Gauge Test for Vruddhi Rebar Couplers

At Vruddhi, we ensure the highest precision and quality of our Rebar Couplers by performing the Go/No-Go Gauge Test.

Reproducibility and Quality Assurance:

At Vruddhi, we pride ourselves on our ability to produce the same high-quality product consistently over time, thanks to our stringent quality assurance processes. Our commitment to reproducibility ensures that every product we manufacture meets the highest standards without variation.

What is the Go/No-Go Gauge Test?

The Go/No-Go Gauge Test is a critical quality control procedure used to verify the dimensional accuracy of our Rebar Couplers. This test involves using a specially designed gauge that has two ends: the "Go" end and the "No-Go" end.

How Does It Work?

> Go End: The "Go" end of the gauge should fit easily into the coupler, ensuring that the coupler's dimensions are within the acceptable range.

> No-Go End: The "No-Go" end should not fit into the coupler, ensuring that the coupler is not oversized beyond the specified limits.Image: [Insert Go/No-Go Gauge Test Image]

By using this test, we can guarantee that each coupler meets the precise specifications required for reliable and secure connections in construction projects. This test, along with our other rigorous quality assurance procedures, ensures that Vruddhi Rebar Couplers consistently deliver the performance and reliability that our clients expect.

Unique Identification Number (UIN) for Vruddhi Rebar Couplers

At Vruddhi, we implement a Unique Identification Number (UIN) system to ensure the highest level of traceability and quality control for our Rebar Couplers. Each coupler is marked with a unique code, allowing for end-to-end traceability throughout the entire supply chain.Benefits of UIN:

1. Traceability: The UIN enables us to track each coupler from the raw material stage through to final delivery, ensuring complete traceability.

2. Quality Assurance: With the UIN, we maintain strict quality norms across the entire supply chain, guaranteeing that only the highest quality couplers reach our clients.

3. Accountability: The unique code on each coupler holds us accountable for every step of the manufacturing and delivery process, ensuring consistency and reliability.

By implementing the UIN system, Vruddhi ensures that our Rebar Couplers meet stringent quality standards and deliver exceptional performance in all construction applications.

Vruddhi Couplers Testing

Our commitment to quality is unwavering, and we subject our products to rigorous testing to ensure their reliability.

- Static Tensile Test : The Tensile strength of the mechanical splice shall be as follows:

(a) If greater than 130% of Fy; Location of failure can be anywhere

(b) If lesser than 130% of Fy; Location of failure should be outside the length of the mechanical splice(L)]

Fy = Minimum yield stress as per the rebar gradeL = 2D (D is size of rebar)] - Slip Test : Total slip for the spliced sample should be less than 0.10 mm.

- 100 Cycles Test : The rebar coupler joint shall withstand 100 cycles of stress variation, simulating the loading experienced in tall and stack-like structures.

- Low Cycle Fatigue Test : The mechanical splices shall withstand 10,000 cycles of alternating tension and compression loads.

- High Cycle Fatigue Test : The mechanical splices shall withstand 20 Lakh cycles of alternating tension and compression loads.

Rebar Preparation Process

a) Cold Forged

- Flat cut rebars

- Cold forging

- Threading

- Coupler fixing

b) Parallel

- Flat cut rebars

- Threading

- Coupler fixing