Description

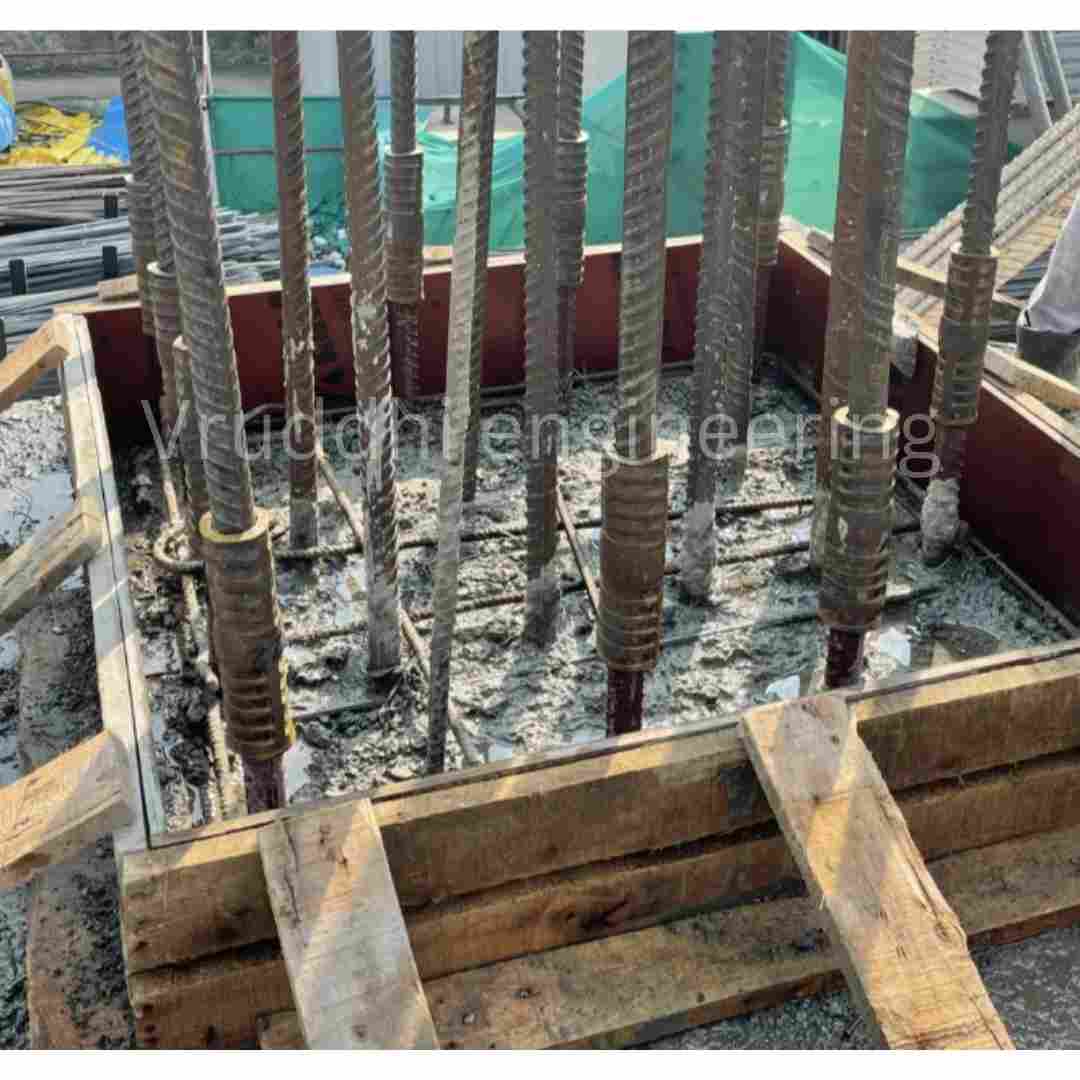

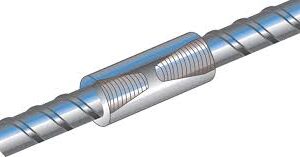

The Coupler Sleeve is crimped on to the rebars that need to be connected by using a Handheld Jack on-site supported by a Hydraulic Power Pack.

Product Features

- Connect rebars of the same or different diameter

- No use of chemicals or flammable gas

- No need for specialized bar end preparation

- On-site crimping service by our Experience Team

- Available for sizes Ø 16 mm to 40 mm

Applications

- In cases where rebar end preparation is not possible

- Structural retrofitting, strengthening, and repairing

Bar Preparation

- Use flat-cut rebars for the application.

- No special bar end preparation or threading is needed.

- Connect two non-threaded rebars using a hydraulic crimping process on-site.

Benefits

Cost Saving – Lesser Steel Consumption

Higher UTS Than That of Parent Rebar

Shortens Project Timeline

No Torque Wrench Required

Solves Bar Congestion

Improvement in Concrete Flow

Benefits

Experience a multitude of benefits when you choose Vruddhi Rebar Couplers:

- Cost Savings: Vruddhi Rebar Couplers offer substantial cost savings by reducing steel consumption in construction projects. This efficient alternative to lap joints not only lowers material costs but also shortens project timelines, minimizing labor expenses. The result is a significant overall reduction in construction expenditures, making Vruddhi Couplers a smart and cost-effective choice for your projects..

- Load Transfer Independence:

Vruddhi Rebar Couplers provide load transfer independence, ensuring the structural integrity of your construction

regardless of concrete quality or grade. This benefit guarantees consistent performance and reliability, reducing the risk of structural issues and offering peace of mind in diverse construction scenarios. - Project Timeline Shortening: Vruddhi Rebar Couplers expedite project timelines significantly. Their quick and efficient installation reduces construction duration, leading to earlier project completion. This time-saving advantage not only enhances project efficiency but also minimizes labor and overhead costs, making Vruddhi Couplers a valuable asset for timely project delivery.

- No Torque Wrench Required : Vruddhi Rebar Couplers offer the advantage of not requiring a torque wrench for installation. This simplifies the assembly process, reducing the need for specialized tools.

- Bar Congestion Solution: Vruddhi Rebar Couplers offer an effective solution by reducing congestion, ensuring proper concrete flow, and preventing potential weaknesses. This not only enhances structural strength but also guarantees the long-term durability of your construction projects.

- Improved Concrete Flow: Vruddhi Rebar Couplers facilitate improved concrete flow during construction. By

eliminating the need for lap joints and reducing rebar congestion, they create a smoother and more efficient concrete

pouring process to avoid Honeycomb Formation. - Full Performance Rebar Splicing: Vruddhi Rebar Couplers guarantee full performance rebar splicing. It performs Adequately under Tension, Compression, Fatigue Loads to provide rebar performance. Compliant with IS 16172 standards, they ensure reliable and robust connections in construction projects. This adherence to quality and strength specifications assures builders and engineers of consistent and dependable performance, vital for the integrity of structures.

Vruddhi Rebar Coupler Testing

To ensure the highest quality and performance of Vruddhi Rebar Couplers, we conduct a series of rigorous tests. Below are the key tests with their detailed descriptions:

1) Static Tensile Test

Image: [Insert Static Tensile Test Image]

The Static Tensile Test measures the maximum tensile strength of the rebar coupler. In this test, the coupler is subjected to increasing tension until it fails. This ensures that our couplers can withstand the maximum stress they might encounter in a construction environment.2) Slip Test

Image: [Insert Slip Test Image]

The Slip Test evaluates the coupler's ability to maintain a secure grip on the rebar under stress. This test involves applying a load to the coupler and measuring any movement or slip between the rebar and the coupler. This ensures that our couplers provide a reliable and stable connection.

3) 100 Cycle Test

Image: [Insert 100 Cycle Test Image]

The 100 Cycle Test assesses the durability of the coupler through repeated loading and unloading cycles. The coupler is subjected to 100 cycles of load application to simulate the stress it will experience over time in real-world conditions. This test ensures that our couplers can endure repeated stress without compromising their integrity.

4) Low Fatigue Test

Image: [Insert Low Fatigue Test Image]

The Low Fatigue Test evaluates the coupler’s performance under low cyclic loads. This test involves applying low levels of stress repeatedly to the coupler to simulate the conditions it will face in certain construction environments. This ensures that our couplers perform reliably under such conditions.

5) High Fatigue Test

Image: [Insert High Fatigue Test Image]

The High Fatigue Test measures the coupler’s endurance under high cyclic loads. The coupler is subjected to high levels of stress repeatedly to simulate the extreme conditions it might face. This test ensures that our couplers maintain their integrity and performance even under severe stress.

Unique Identification Number (UIN) for Vruddhi Rebar Couplers

At Vruddhi, we implement a Unique Identification Number (UIN) system to ensure the highest level of traceability and quality control for our Rebar Couplers. Each coupler is marked with a unique code, allowing for end-to-end traceability throughout the entire supply chain.

Benefits of UIN:

1. Traceability: The UIN enables us to track each coupler from the raw material stage through to final delivery, ensuring complete traceability.

2. Quality Assurance: With the UIN, we maintain strict quality norms across the entire supply chain, guaranteeing that only the highest quality couplers reach our clients.

3. Accountability: The unique code on each coupler holds us accountable for every step of the manufacturing and delivery process, ensuring consistency and reliability.

By implementing the UIN system, Vruddhi ensures that our Rebar Couplers meet stringent quality standards and deliver exceptional performance in all construction applications.

Rebar Preparation Process

a) Cold Forged

- Flat cut rebars

- Cold forging

- Threading

- Coupler fixing

b) Parallel

- Flat cut rebars

- Threading

- Coupler fixing