Description

What is Crosshole Sonic Logging Tube?

Cross-hole sonic logging (CSL) tubes are essential components used in the testing of deep foundations, particularly drilled shafts and bored piles. These tubes are embedded in concrete structures to facilitate the cross-hole sonic logging process, which evaluates the integrity and quality of the concrete.Method of CSL Testing

- The transmitter and receiver are placed into separate, adjacent tubes within the concrete structure.

- The transmitter sends ultrasonic pulses through the concrete to the receiver in the adjacent tube.

- The receiver detects the ultrasonic pulses that travel through the concrete.

- This process is repeated at various depths by simultaneously lowering and raising the transmitter and receiver, covering the entire depth of the concrete structure.

- This method provides insights into concrete quality and homogeneity, allowing for timely adjustments to ensure structural integrity.

About Vruddhi Sonic Tube

- Vruddhi Sonic Tubes (VST) provide a reliable method for assessing the structural integrity of concrete in deep foundation structures like diaphragm walls, bored piles, drilled shafts, concrete piles, and augercast piles.

- Made of thin steel with a bell-shaped end, VST tubes are installed within the rebar cage before concrete pouring. The bell-mouth design ensures easy connection, reducing labor costs.

- Available in various diameters, VST tubes feature a specially designed rubber gasket for simple installation and perfect sealing, preventing material entry and maintaining tube integrity.

- Using VST tubes also facilitates efficient and accurate cross-hole sonic logging (CSL) testing, providing critical data for maintaining the safety and stability of the structure.

- These features make VST tubes an essential component for quality assurance in modern construction projects.

Advantages of using Vruddhi Sonic Tubes

- No threading on pipes.

- Easy fixing to rebar cage.

- No welding required at job site.

- Fast and easy installation by labours.

- No special equipment required for installation.

- Push-fit mark ensures full engagement, facilitating easy assembly.

Specifications

Quality Assurance

Vruddhi Sonic Tubes are Manufactured under Quality Management System – ISO 9001:2015 and tested for following test:

- Tensile test for Sonic Tubes

- Pull-out test for Ears

- Hydrostatic Pressure test

- Crush test

VST has successfully passed the above test

Storage Guidelines

- Cover steel tubes with tarpaulin.

- Store steel tubes in a covered area or enclosed container.

- Avoid exposure to environmental conditions such as humidity, rain, and heat.

Assembly Instructions

- Step 1 . Install a bottom cap onto the first sonic tube.

- Step 2 . Fix the sonic tube to the rebar cage by tying the steel wire around the fixing ears and tube.

- Step 3 . Fix the next tube to the rebar cage as the step.

- Step 4 . Connect the two tubes completely.

- Step 5 . Connect all the tubes and lower the cage. Repeat the process for all other tubes and cage segments.

We also offer Rebar Coupler, TMT bars, Concial Wall Tie for aluminium formwork, MS Structures & other value added engineering products for construction

To know more about how Vruddhi Sonic Tubes can enhance your construction projects, contact us at +91 88281 36028.

Benefits

Process

Step 1

90º cutting

Step 2

Forging

Step 3

Threading

Step 4

Couplers Fixing

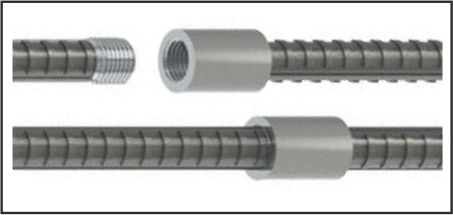

Rebar Preparation Process

a) Cold Forged

- Flat cut rebars

- Cold forging

- Threading

- Coupler fixing

b) Parallel

- Flat cut rebars

- Threading

- Coupler fixing